Shenzhen Panwin Machinery&Equipment Co Ltd.

Main Products:

Jixiang Rd Longcheng Street Longgang District Shenzhen China 518172

+86-755-84706259

1. Product Introduction of Water Jet Blasting dust dirt cleaning machine parts Lance

For this Water Jet Blasting dust dirt cleaning machine parts Lance,We Shenzhen Panwin offers Various Kinds of high pressure lances. The lances are designed for any 40Kpsi water blasting application. We have a large number of products and inventory, high pressure pipe can be customized according to the length.

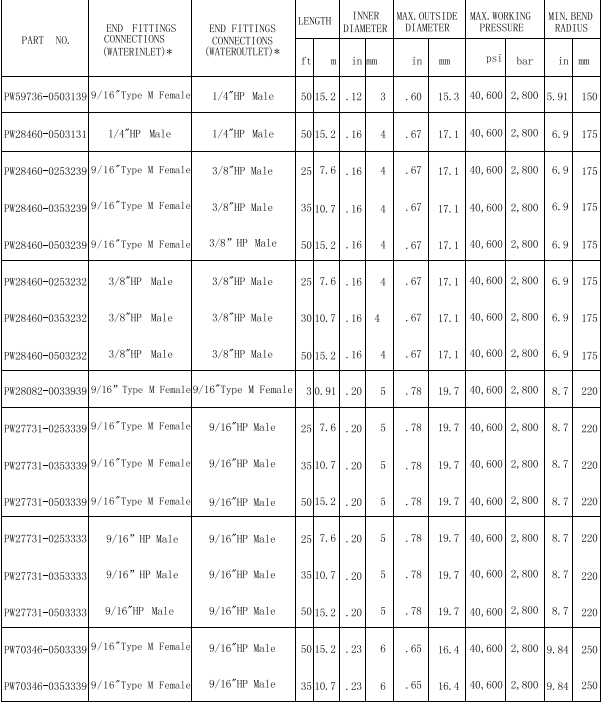

2. Product Parameter (Specification) of Water Jet Blasting dust dirt cleaning machine parts Lance

The Water Jet Blasting dust dirt cleaning machine parts flex Lances are uncovered lances used for the cleaning of small diameter tubes in Heat-exchange,Condensers and boilers.etc.

Details specification as follows:

3. Product Feature And Application of Water Jet Blasting dust dirt cleaning machine parts Lance

The Water Jet Blasting dust dirt cleaning machine parts Lance is Max pressure 40,600psi, and various length available, and it has the various connection types.

4. Deliver, Shipping And Serving of Water Jet Blasting dust dirt cleaning machine parts Lance

For the Water Jet Blasting dust dirt cleaning machine parts Lance packing,the freight charge no include in the price, and freight charge depend on delivery way, airfreight,ocean shipment, or Railway, the freight differentiate in different regions, the goods do not include freight and wooden frame packaging costs.

For the big weight parts, like Manifold, Gland Nut, hand Control gun etc, we will pack package with strong plywood inside with thick foam fill bottom and four side to protect the parts.

For the Medium size item like Plunger, 4" 6" Bend Pipe Cleaning Nozzle self-rotary nozzles etc we will pack with solid plastic box and covered with thick foam to avoid any damage and pack in carton box or plywood depend on customer requested.

For the small parts, like M10 Nozzles, 3/8-24 Nozzles various seal accessories, etc, we will thick polybag or bubble bag and covered with thick foam to prevent any possible damage, and put in the carton box or plywood as customers requested.

5. FAQ

1: How important to keep the nozzles clean?

In the Water Hydro cleaning process, the blocked nozzle will not have good clean effect ,and the clogged nozzles also can increase the backward pressure on the power pump, and cause damage to the pump, so regular clean or even replace nozzles is important.

2: What terms of payment do you accept ?

For large quantity regular orders, 30% T/T advance 70% T/T before shipment; for special OEM orders, 30% T/T advance 70% T/T before shipment; for small quantity or sample order, 100% T/T in advance.

3: In the water Blasting cleaning process,What two factors is more important, pressure(bar) or Flow Volume(LMP)?

The two factors pressures and Flow Volume are both critically important for your optimized best cleaning performance and spray effect, the pressure will determine your spraying power, and the flows Volume take dirt and sediment etc away.

6.Product qualification and Patent certificate

Shenzhen Panwin Machinery&Equipment Co.,Ltd are a professional manufacturer specializing Hydro Jet Blasting Cleaning&Cutting machine parts,We strictly controls the whole process of product production according to the quality standard ISO9001-2015 and passed the quality Certificate, Years of experience in the production and design of Ultra-high pressure accessories and machinery, not only We are winning the trust and long-term cooperation of customers, but also accumulated rich design experience and industry sensitivity for us. We have been expanding and innovate to satisfy the market and customers needs and practical applications.

|

Shenzhen Panwin Machinery&Equipment Co., Ltd. is a well-established company with the aim of providing efficient and high-quality Ultra-hi-pressure water-jet component&Partss to our worldwide customers for industrial cleaning& cutting. We manufacture a wide range of Ultra-High Pressure Pump Parts, including Self-Rotary nozzles, Sapphire nozzles, Universal Valve, as well as water-jet cutting machine parts, Flow KMT WSI etc. Over Panwin 10 years of professional R&D team dedicated to providing our customer excellent quality parts compete outstanding in the industry. |

|

|

Innovation mindset: Unyielding Innovation is the driving-force and direction for an enterprise to continue its healthy development. In the face of fierce industry competition, Innovation is the best way out under the trend of intelligent manufacturing and high-end production upgrading . We Panwin teams exert no effort to build the Innovation mindset in every employee. We encourage innovation, reward optimization suggestions of our staff on manufacturing process, production technology, cost reduction, management performance, etc., and continuously improve production efficiency and productivity. |

|

Business Strategy: We Pan-win adopt Muti-Win business philosophy and all staff fight for this strategy. In intense business competition, we always insist on sharing profit, mutual benefit with customers, employees, investors, suppliers and service providers. Together we can combine with plenty of resources, encourage innovation actively.Hand-in-hand we can produce better quality high-pressure products continuously. We are endeavoring to reach yearly financial goal and operational performance targets, guide work with performance&Target. Help customers wholeheartedly, grow and win together with our clients. |

|

|

|

Mission Statement: We take promoting the application and development of hi-Pressure water Jet Blasting cleaning as our mission&responsibility, learn foreign advanced technology, constantly innovate and keep High-quality products as first-priority, promote Ultra-high-pressure Water-Jet cleaning, improve efficiency, and make unremitting efforts to provide our customers with reliable products. Our mission&Vision provides excellent quality Ultra-high pressure water-jet cleaning components and parts and acts as leading water-jet clean industry parts and service provider. |

English

English Español

Español Português

Português русский

русский français

français 日本語

日本語 Deutsch

Deutsch Tiếng Việt

Tiếng Việt Italiano

Italiano Nederlands

Nederlands ไทย

ไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা

বাংলা Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türk

Türk Gaeilge

Gaeilge عربى

عربى Indonesia

Indonesia norsk

norsk اردو

اردو čeština

čeština Ελληνικά

Ελληνικά Українська

Українська Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақ

Қазақ Euskal

Euskal Azərbaycan

Azərbaycan slovenský

slovenský Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Српски

Српски 简体中文

简体中文 Esperanto

Esperanto Afrikaans

Afrikaans Català

Català עִברִית

עִברִית Cymraeg

Cymraeg Galego

Galego 繁体中文

繁体中文 Latvietis

Latvietis icelandic

icelandic יידיש

יידיש Беларус

Беларус Hrvatski

Hrvatski Kreyòl ayisyen

Kreyòl ayisyen Shqiptar

Shqiptar Malti

Malti lugha ya Kiswahili

lugha ya Kiswahili አማርኛ

አማርኛ Bosanski

Bosanski Frysk

Frysk ជនជាតិខ្មែរ

ជនជាតិខ្មែរ ქართული

ქართული ગુજરાતી

ગુજરાતી Hausa

Hausa Кыргыз тили

Кыргыз тили ಕನ್ನಡ

ಕನ್ನಡ Corsa

Corsa Kurdî

Kurdî മലയാളം

മലയാളം Maori

Maori Монгол хэл

Монгол хэл Hmong

Hmong IsiXhosa

IsiXhosa Zulu

Zulu Punjabi

Punjabi پښتو

پښتو Chichewa

Chichewa Samoa

Samoa Sesotho

Sesotho සිංහල

සිංහල Gàidhlig

Gàidhlig Cebuano

Cebuano Somali

Somali Точик

Точик O'zbek

O'zbek Hawaiian

Hawaiian سنڌي

سنڌي Shinra

Shinra հայերեն

հայերեն Igbo

Igbo Sundanese

Sundanese Lëtzebuergesch

Lëtzebuergesch Malagasy

Malagasy Yoruba

Yoruba