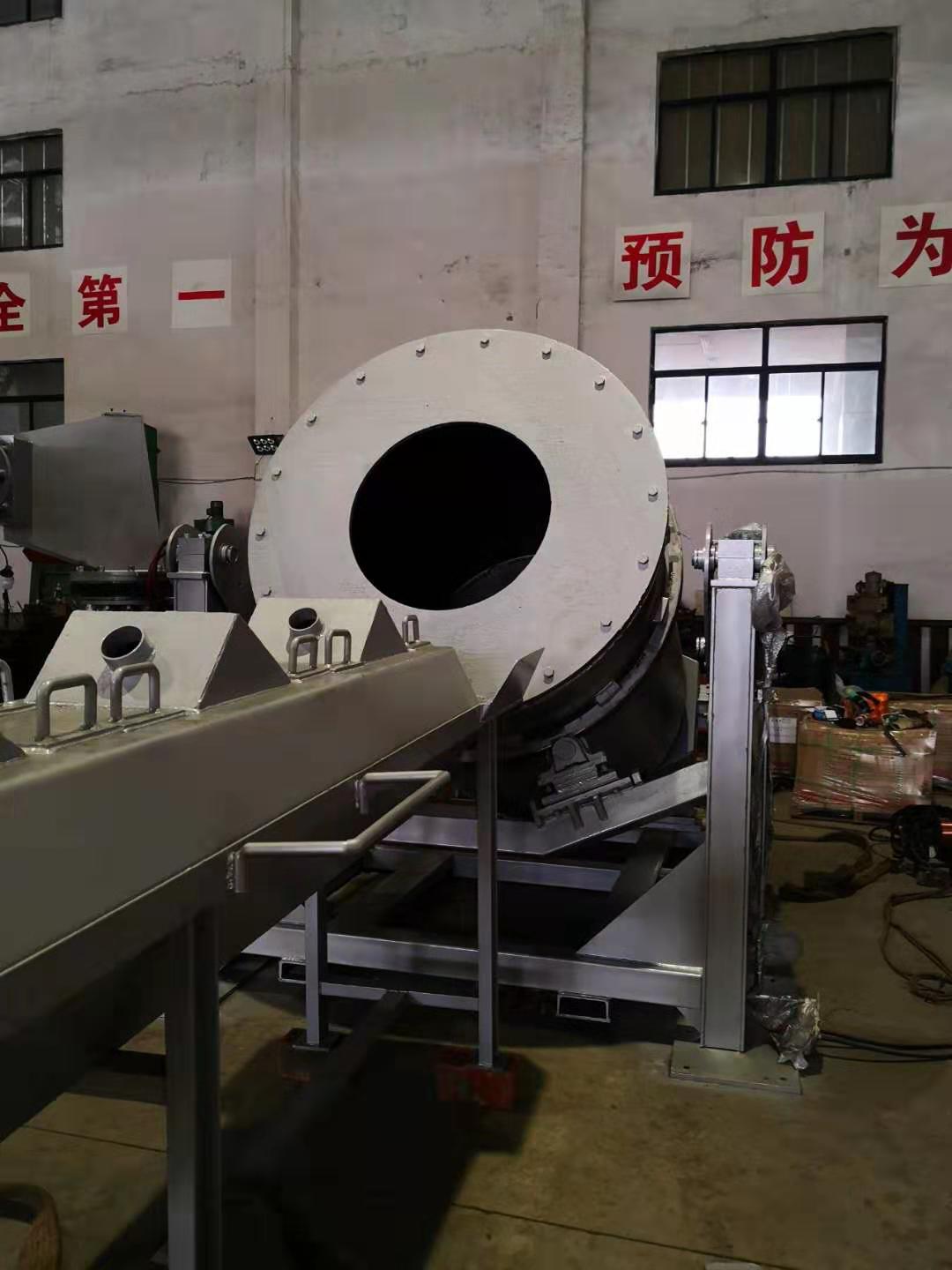

The energy consumption of smelting waste aluminum using a conventional reverberatory furnace is about 1000kw/t, equivalent to 100Nm ³/ Natural gas or 100L/t oil. Using a tilting rotary furnace can save 25%. The decrease in energy consumption is mainly due to the significant improvement of heat transfer in the rotary furnace and the dual channel arrangement of the burners, resulting in a large amount of waste heat recovery in the flue gas.

The tilting rotary furnace adopts proportional integral differential control mode (IP) D to control the amount of fuel and combustion air. At the same time, this control is continuous and can automatically adjust the temperature according to the charging amount, making the smelting process in an optimized state. When smelting in a reverberatory furnace, the temperature of the furnace top or upper furnace wall is adjusted to 1100 ℃, while the setting temperature of a tilting rotary furnace is 750 ℃. 25% energy savings come from the improvement of temperature difference and thermal efficiency. The productivity of the tilting rotary furnace is improved by the use of fully automated charging machines, automated slag tanks (boxes), and automated slag removal, which means only simple operations are carried out during the smelting process; The number of operators can be reduced by at least two. One person can operate two furnaces with high thermal efficiency and fully automated control of the smelting process to achieve optimal melting speed. The melting cycle of the tilting rotary furnace can be reduced to less than 4 hours, which means that depending on the furnace capacity, each furnace can melt 6 to 8 furnaces per day, which is equivalent to a 15t furnace melting 90 tons of recycled aluminum every 24 hours, and a 5t furnace can melt about 40 tons.

Compared to a reverberatory furnace, a tilting rotary furnace has a much wider range of waste capacity, and can effectively melt from low-level slag, chips, and cans to process waste. Therefore, recycled aluminum enterprises can use low-level waste to smelt higher grade or even recycled aluminum, achieving good economic benefits. Low quality waste materials such as chips and slag cannot be melted using a reverberatory furnace.

From the above introduction, it can be seen that the main advantages of tilting rotary furnaces are reduced burning loss and increased productivity, which is due to the comprehensive automation control of melting temperature, time, and combustion parameters.

English

English Español

Español Português

Português русский

русский français

français 日本語

日本語 Deutsch

Deutsch Tiếng Việt

Tiếng Việt Italiano

Italiano Nederlands

Nederlands ไทย

ไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা

বাংলা Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türk

Türk Gaeilge

Gaeilge عربى

عربى Indonesia

Indonesia norsk

norsk اردو

اردو čeština

čeština Ελληνικά

Ελληνικά Українська

Українська Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақ

Қазақ Euskal

Euskal Azərbaycan

Azərbaycan slovenský

slovenský Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Српски

Српски 简体中文

简体中文 Esperanto

Esperanto Afrikaans

Afrikaans Català

Català עִברִית

עִברִית Cymraeg

Cymraeg Galego

Galego 繁体中文

繁体中文 Latvietis

Latvietis icelandic

icelandic יידיש

יידיש Беларус

Беларус Hrvatski

Hrvatski Kreyòl ayisyen

Kreyòl ayisyen Shqiptar

Shqiptar Malti

Malti lugha ya Kiswahili

lugha ya Kiswahili አማርኛ

አማርኛ Bosanski

Bosanski Frysk

Frysk ជនជាតិខ្មែរ

ជនជាតិខ្មែរ ქართული

ქართული ગુજરાતી

ગુજરાતી Hausa

Hausa Кыргыз тили

Кыргыз тили ಕನ್ನಡ

ಕನ್ನಡ Corsa

Corsa Kurdî

Kurdî മലയാളം

മലയാളം Maori

Maori Монгол хэл

Монгол хэл Hmong

Hmong IsiXhosa

IsiXhosa Zulu

Zulu Punjabi

Punjabi پښتو

پښتو Chichewa

Chichewa Samoa

Samoa Sesotho

Sesotho සිංහල

සිංහල Gàidhlig

Gàidhlig Cebuano

Cebuano Somali

Somali Точик

Точик O'zbek

O'zbek Hawaiian

Hawaiian سنڌي

سنڌي Shinra

Shinra հայերեն

հայերեն Igbo

Igbo Sundanese

Sundanese Lëtzebuergesch

Lëtzebuergesch Malagasy

Malagasy Yoruba

Yoruba