Xiangtan Lufeng Machinery Co., Ltd

Main Products:rotary furance ,ingot casting machine , electrolysis machine system

Building B6, Accelerator Park, No. 18 Gaoxin Road, Xiangtan, Hunan Province, China

+86-13637325838

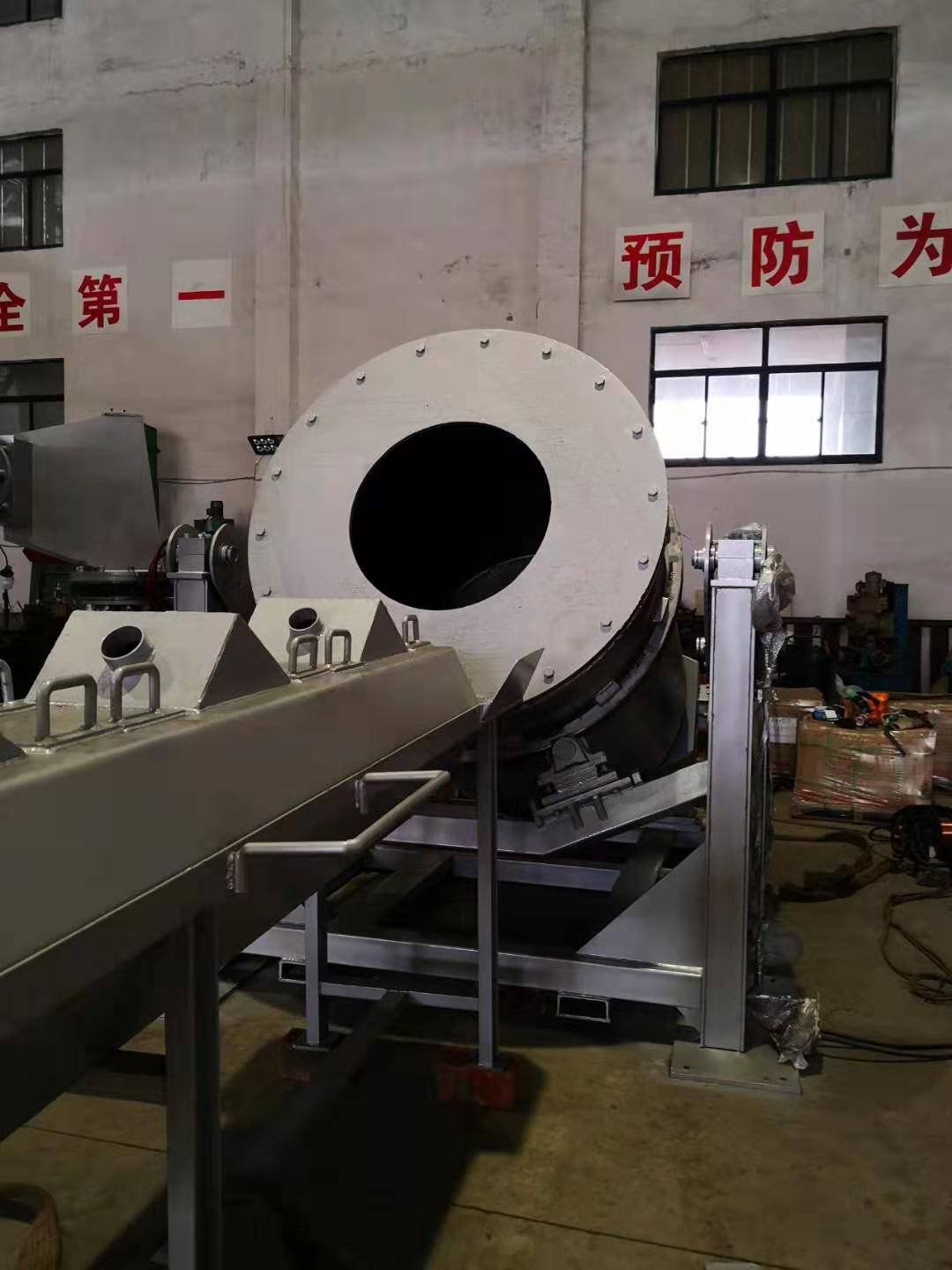

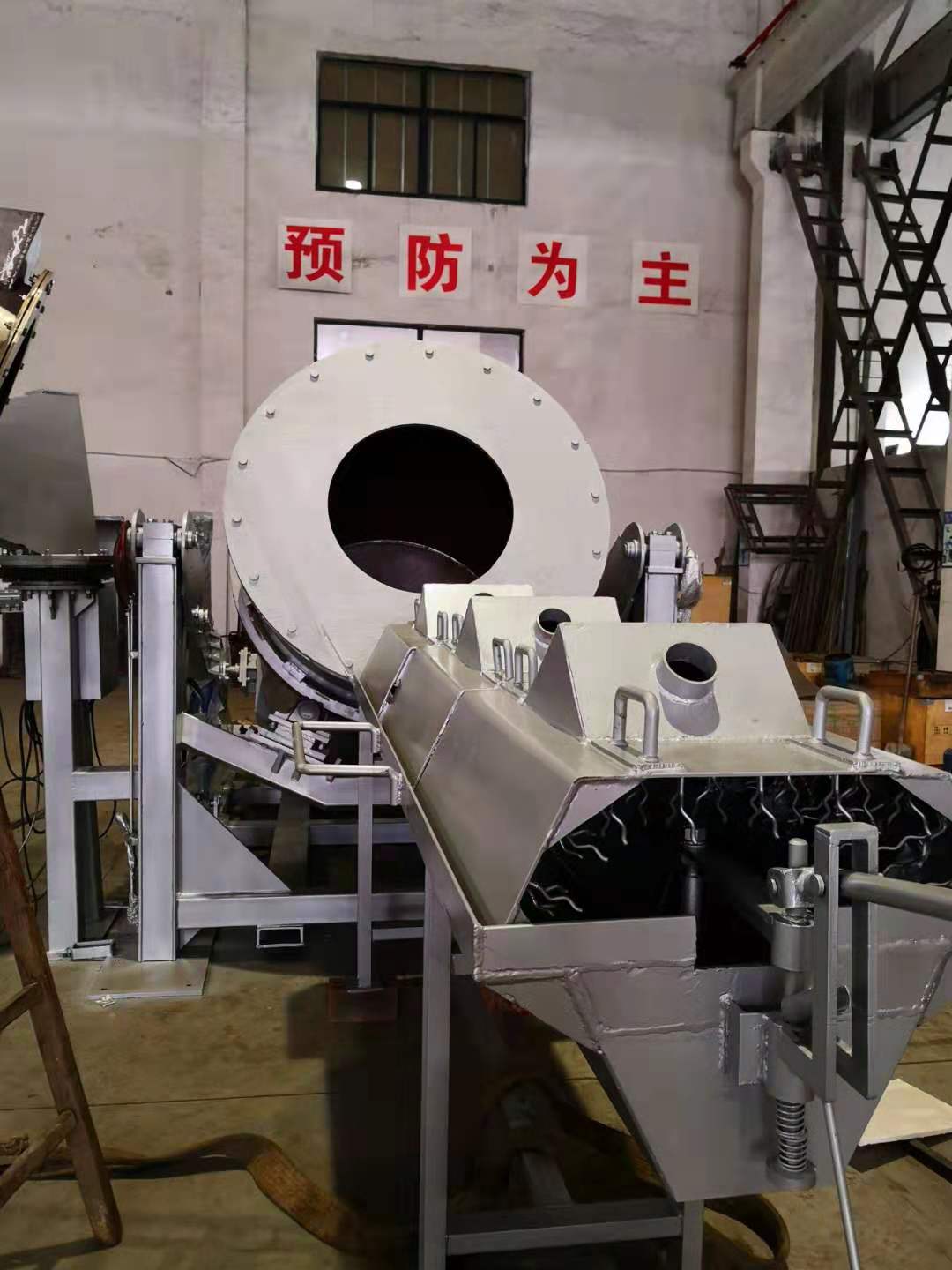

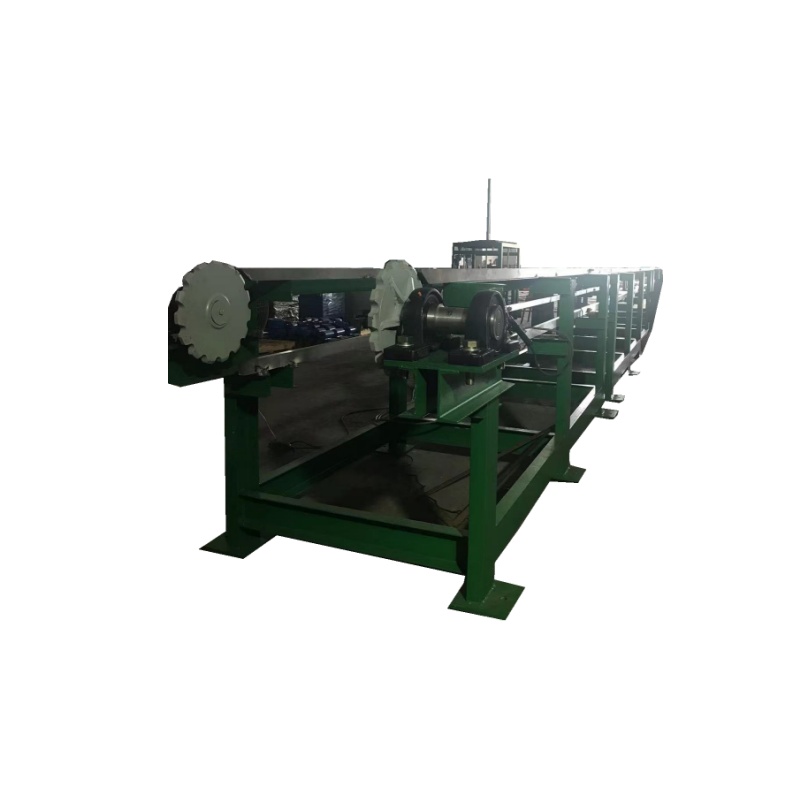

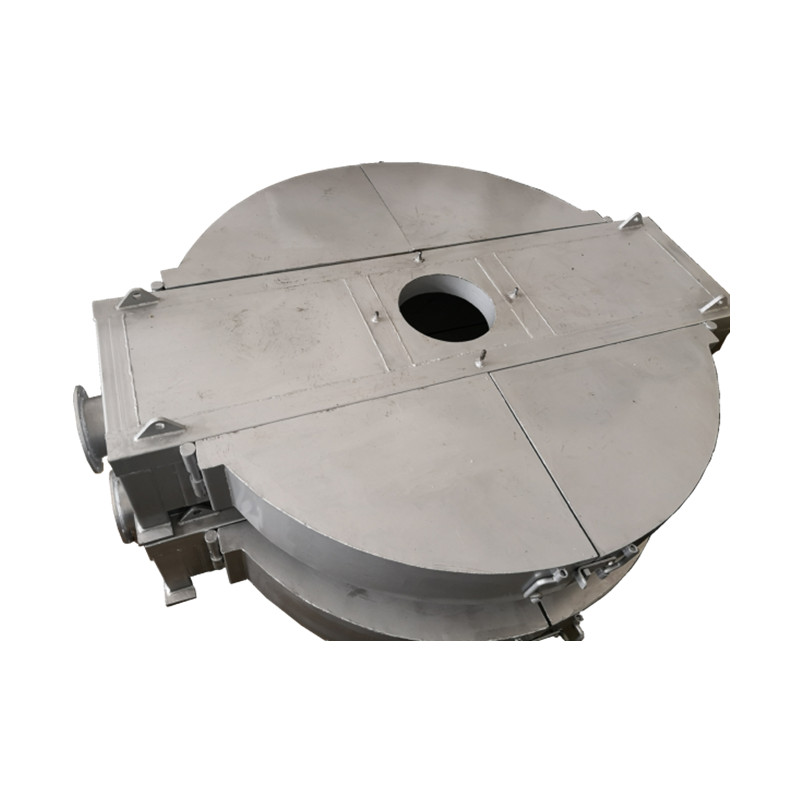

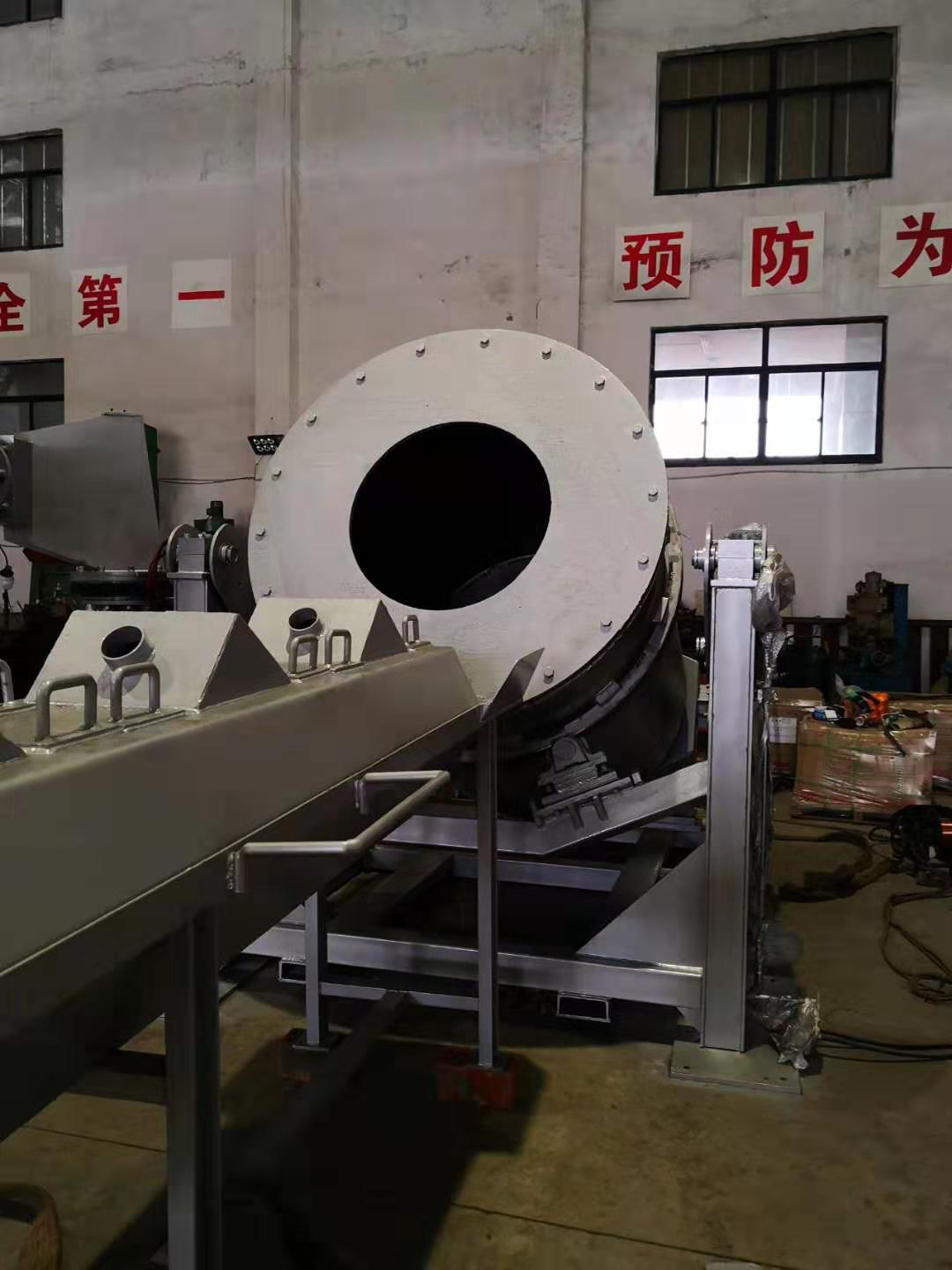

PRODUCT NAME: 5T lead aluminum copper Natural Gas/Oil Rotary Tilting Furnace

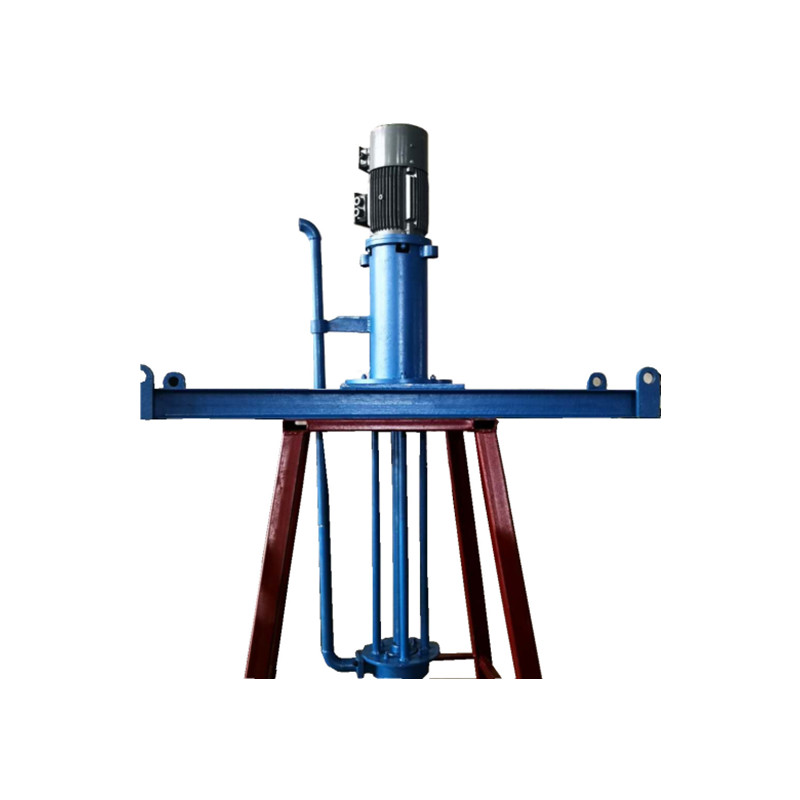

Rotary tilting refining furnace

The rotary tilting refining furnace is mainly used for the pyrometallurgical refining of recycled metals (mostly used for impure copper). In order to improve the technical and economic comprehensive indicators of the tilting refining furnace, it is best to have a copper grade higher than 90% when entering the furnace. For raw materials with lower copper grades, it is best to first undergo pre-treatment in the blast furnace and blowing furnace before entering the tilting furnace.

The furnace body of the rotary furnace is installed on a rotating frame, which, under the action of a hydraulic cylinder, can tilt the furnace body within a certain angle range to achieve process actions such as feeding, melting, and dumping slag. At the same time, the furnace body can rotate around its axis under the action of the transmission mechanism; The rotary motion improves the heating efficiency of the furnace and is of great significance for the overheating of the molten metal.

When melting metal in this furnace, a certain amount of slag forming agent needs to be added. The molten slag forming agent and slag liquid have a protective effect on solid and liquid metals, which can prevent metal oxidation.

The burning loss rate of elements such as silicon and manganese in a rotary cupola is equivalent to that of a coke burning cupola. The content of carbon elements in the rotary furnace is decreasing, so it is necessary to add a certain amount of carburizing agent (coke or graphite) to the furnace material.

PRODUCT PICTURES:

SPECIFICATIONS:

Aluminum copper lead Melting rotary tilting Furnace features:

1. Model: fixed furnace, double chamber furnace, side pool aluminum scrap furnace, tilting furnace, rotary furnace

2. Specification: 1.5 tons to 100 tons

3. Melting speed: 3~12t/h

4. Fuel: natural gas, liquefied gas, heavy oil, diesel, tire oil;

5. Raw materials: aluminum ingot, aluminum scrap, scrap aluminum, pop can,lead battery , copper ore ect.

6. Equipped with burners: regenerative, top mounted, top mounted, integral and bottom mounted;

Xiangtan Lufeng Machinery Co., Ltd. was established in 2010 and is located in the Industrial Park of Hunan Xiangtan High-tech Zone. Through more than 10 years of precipitation and development, Lufeng company has made many achievements in the design and manufacture of high-quality copper&lead&zinc smelting equipment.

Today, Lufeng has become one of the best manufacturers of high-quality smelting equipment in China and abroad, such as copper&lead smelting furnace, linear ingot casting machine, disc ingot casting machine, lead pot refining system, lead-acid battery crushing and sorting system, copper&lead&zinc electrolysis system, etc.

English

English Español

Español Português

Português русский

русский français

français 日本語

日本語 Deutsch

Deutsch Tiếng Việt

Tiếng Việt Italiano

Italiano Nederlands

Nederlands ไทย

ไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা

বাংলা Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türk

Türk Gaeilge

Gaeilge عربى

عربى Indonesia

Indonesia norsk

norsk اردو

اردو čeština

čeština Ελληνικά

Ελληνικά Українська

Українська Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақ

Қазақ Euskal

Euskal Azərbaycan

Azərbaycan slovenský

slovenský Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Српски

Српски 简体中文

简体中文 Esperanto

Esperanto Afrikaans

Afrikaans Català

Català עִברִית

עִברִית Cymraeg

Cymraeg Galego

Galego 繁体中文

繁体中文 Latvietis

Latvietis icelandic

icelandic יידיש

יידיש Беларус

Беларус Hrvatski

Hrvatski Kreyòl ayisyen

Kreyòl ayisyen Shqiptar

Shqiptar Malti

Malti lugha ya Kiswahili

lugha ya Kiswahili አማርኛ

አማርኛ Bosanski

Bosanski Frysk

Frysk ជនជាតិខ្មែរ

ជនជាតិខ្មែរ ქართული

ქართული ગુજરાતી

ગુજરાતી Hausa

Hausa Кыргыз тили

Кыргыз тили ಕನ್ನಡ

ಕನ್ನಡ Corsa

Corsa Kurdî

Kurdî മലയാളം

മലയാളം Maori

Maori Монгол хэл

Монгол хэл Hmong

Hmong IsiXhosa

IsiXhosa Zulu

Zulu Punjabi

Punjabi پښتو

پښتو Chichewa

Chichewa Samoa

Samoa Sesotho

Sesotho සිංහල

සිංහල Gàidhlig

Gàidhlig Cebuano

Cebuano Somali

Somali Точик

Точик O'zbek

O'zbek Hawaiian

Hawaiian سنڌي

سنڌي Shinra

Shinra հայերեն

հայերեն Igbo

Igbo Sundanese

Sundanese Lëtzebuergesch

Lëtzebuergesch Malagasy

Malagasy Yoruba

Yoruba